| 10/14/03 |

This thing is starting to look like something! Trimmed

the J-channel longerons. Forgot to do both ends so I'll have to pull

them out and work the front ends, no biggie but it kept me from clecoing the

most forward bulkhead in place. Garage now holds two vehicles and all

plane parts.

|

| 10/15/03 |

Finished the J-channel longerons. Started to rivet

them to the skins. Is anyone else having problems getting the aft

bulkheads and the lower tail skin to match. What a tight fit.

Managed to massage the bulkheads so that it fits but it took a bit of fuss

for sure.

|

| 10/16/03 |

Made sure the fuselage was straight with no twist per the

instructions using a plum bob. Nice and straight. Match drilled

the J-channel riveting every forth rivet.

|

| 10/17/03 |

Friday, payday and time to drill 4 gazillion holes.

Drilled out every hole in the aft fuselage except the 706 bulkhead as per

plans. Now to debur and dimple every last one of them. No need

for a picture of that boredom. Tomorrow I get the second inspection of my

kit so far at my local EAA chapter 96 by Dave Bristol, our local Technical

Counselor. Dave's inspected my work so far and it passed. Dave

has an awesome RV6 hangared there at Compton. Drop by on any third

Saturday of the month for an enlightening monthly meeting, which just

happens to be tomorrow. |

| 10/18/03 |

Dave noticed a few rivets which were a bit too flat on the

firewall but overall he said my work was very good. We had some

confusion about whether the bushings on the control stick mounts should be a

bit longer than the part around it so the bushing does not rotate about the

bolt. I'll post a question to "the group".

Came home and countersunk, dimpled, deburred, etc, etc, etc. Here

are the aft and lower fuselage skins ready to go. Damn now I just

remembered that I didn't debur the edges.

|

| 10/19/03 |

Today I had my worst day ever. I couldn't put a rivet

in correctly if my life depended on it. Spent almost the entire day

trying to get the rivets set correctly in the 711, 712 tail assembly.

I realized that my 3x rivet gun is having problems. I just can't get

"a little" air through the gun. It either liquefies the rivets or just

doesn't work at all. I'm fed up with it, damn Sioux gun. I'll

use it to buck solid steel instead. It will probably do an excellent

job at that or titanium. I'm tired of seeing rives 1mm in height. |

| 10/20/03 |

Giving it a rest today. Yesterday beat me up. I

ordered a new Taylor 2x rivet gun today for $150. I didn't want to do

it but I know that Sioux gun is trashed. Ordered a few other parts as

well. |

| 10/21/03 |

Waiting for the rivet gun before tackling the aft fuselage.

Decided to work on the center section. Fabricated the four small

spacers. I cut the 1.5 " diameter holes in the rails with a hole

cutter, and boy does that work slick. Just make sure you have your

part secured to some wood before drilling.

The plans don't *say* to cut four of the eight but that's how many you

need, two R and two L. You *REALLY* should get a pair of nippers.

Cutting the excess off right to the line took only 1 minute per piece.

|

| 10/23/03 |

Started to put the center section together for riveting.

|

| 10/24/03 |

Here it is with the baggage compartment ribs in place.

|

| 10/25/03 |

Time to put the center section skin on and complete the

drilling, deburring and all the other monotonous stuff. I put the seat

covers on to make sure I get the contour perfect on the F715. Tomorrow

I'm ready to prime all the parts and hopefully get some riveted.

|

| 10/26/03 |

Smoke and ash and soot was falling like rain all day so

today was not a good day to prime/paint. I resigned myself to

finishing all the dimpling and to study the plans in advance. Here's

the center section skin and a stack of dimpled parts.

|

| 11/1/03 |

Drove to Corona to get some more Alodine. Spent the

rest of the day alodining all the center section parts and making sure I was

ready to paint tomorrow. |

| 11/2/03 |

Painted all the center section parts. Started to rivet

the seat braces to the aft bulkhead. Found that my compressor (4hp 13

gal.) was on the fritz. Bought a new 6hp 33 gallon compressor

(175psi). This think kicks ass.

|

| 11/8/03 |

Decided to get as many rivets in the aft fuselage as I could

by myself. It wasn't easy but I set up three sawhorses. The

center one had the backing plate on it. This worked very well as

almost every rivet came out perfect. Not for those with weak backs

though as you have to continuously look to see if the backing plate is flush

with the rivets. Will need help with the rivets in the corners.

|

| 11/9/03 |

Spent the day doing all the "little" stuff you see on the

plans. Got all the center section parts completed and ready to rivet

to the skin.

|

| 11/10/03 |

Barry came over and helped me pound in the last of the

rivets in the aft fuselage with exception of the top 5 or 6 so I can get the

longeron in place. Thanks Barry! |

| 11/12/03 |

Can't do any more until pops gets here in two days. I

sold my 57 Chevy and it's going

away tomorrow, bummer. I'm sulking today. |

| 11/15/03 |

Pops came into town yesterday. We're going to make

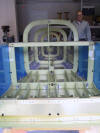

some big progress together. Today we clecoed the center section to the

aft fuselage and mated the side skins for drilling. Here you can see

it's starting to look something like an airplane.

|

| 11/16/03 |

Now it is an airplane. Turned the canoe upside down.

Mounted the longerons and started drilling from the aft end, and drilling,

and drilling and drilling. Bent the bottom corners of the side skin

with no trouble. Do as the instructions say by drilling and clecoing

some angle to the triangle shaped skin tab and bend gently. It takes

some force but in the end it works out fine. Drilled all holes to size

of the side skins. Mounted the 770 bottom skin and drilled to size.

Then mated the firewall. Made sure the clearances were up to snuff.

Inserted rivets through the side skin and longeron to make sure they were

easily inserted and lined up. Held them in place with some duck tape.

Braced the firewall braces as shown in the picture and removed the rivets

one by one and drilled through the metal brace. Finally, here's the

obligatory look at the canoe from the inside.

|

| 1/7/04 |

Well it's been a busy Holiday season. Pops came out at

the middle of November to help me with the riveting job. He stayed for

three weeks. During that time we had the entire canoe completed except

for the final riveting. Here are shots of the parts we fabricated

during that time with notes. (I'm going to keep this up-to-date from

now on :) Here are a few of the parts after priming.

Control rods completed. These are very simple to drill with a tube

holder and drill press. You have to sand away some of the primer from

the insides of the tubes to get the ends to sit without a ton of force.

I decided to go with brakes on both sides. It really doesn't cost

much more and the resale value will be better. I will probably cover

these with a non-skit product. Drilling the holes through the cylinder

base and into the pedal angle is a bitch. I ended up taping 4 washers

together to use as a shim as I drilled. This really helps to have two

people to do it accurately. Just try to make sure the pedals are

similarly aligned when you drill the holes and all will be right with the

world. I also had to cut the torque tubes to size as they were

too long. Drilling the multiple positions for the pedals is a cinch.

Don't bother doing this while on the plane. Take the angles off the

skins and mount to the torque tubes and just measure. Dan C. had this

well documented on his site.

Here, you pre-rivet the spar end brace to the skins Prior to riveting on

the skins. There is no room to do this afterwards. Don't forget!

You will also notice that I sprayed rattle-can primer on all interior

surfaces of the skins where there are rivet holes. Doesn't add much

weight. I can see all the other skin surfaces on the inside of the

airplane so there is no need to primer all interior surfaces.

Here are some shots of the firewall braces. You should spend some

time to get them to fit nice and flush. Also there has been some

question lately as to the *split* in the white corner braces attaching to

the firewall. That's supposed to be there. When drilling these

for the first time use the technique in the instructions and place a rivet

in the holes to line everything up.

Detail of the forward wing attachment point from the inside.

Remember to mark all of the shims on this part top/bottom, inside/outside

and order of the parts. Since you only have to coat them Barely with

primer you will be able to see your markings after priming. If you

don't get these right your rivets will not sit or pass through the holes

properly. Also the plans have a very complicated process to get these

aligned. It's really very simple and the instructions are overly

complicated.

Here I noticed that the bushing holes didn't line up exactly. I

recommend enlarging these holes after you get the skins on and not piece by

piece.

Baggage compartment bracing. Nothing to it.

This is a shot of the bottom of the firewall. Notice that you

dimple the firewall and countersink the angle behind it. You will be

placing the lower cowl hinge on the firewall portion which you will

countersink.

Barry came over about a two weeks ago to help me start final riveting of

the side skins and rest of the fuselage. We made pretty good progress.

There are plenty of rivets to put in. I've ordered the finish kit but

it won't ship until March 22nd so I have *plenty* of time to get this done.

I'm now in slo-mo mode.

Today I started to get my financing inline for the rest of the airplane;

engine, avionics, prop, etc. Here's a costing of those items.

OUCH!!!! I haven't placed my backup instruments here but they will

include Turn/Bank&Slip/Skid, Altimeter, and Airspeed. I want to make

it similar to the Cirrus panel. Very logical layout.

|

QTY |

DESCRIPTION |

VENDOR |

MODEL |

UNIT |

EXTENSION |

|

1 |

Engine |

Penn Yan Aero |

IO-360 horiz induct, LASAR |

$23,641.00 |

$23,641.00 |

|

1 |

Audio Panel w/ 3LMB and Intercom |

Pacific-Coast Avionics |

Garmin GMA 340 |

$1,125.00 |

$1,125.00 |

|

1 |

GPS/MFD/NAV/COMM |

Pacific-Coast Avionics |

Garmin GNS 430 |

$6,390.00 |

$6,390.00 |

|

1 |

VOR/LOC/Glideslope Indicator |

Pacific-Coast Avionics |

Garmin GI 106A |

$1,425.00 |

$1,425.00 |

|

1 |

Transponder w/ Mode S |

Pacific-Coast Avionics |

Garmin GTX 330 |

$3,395.00 |

$3,395.00 |

|

1 |

Transponder encoder |

Pacific-Coast Avionics |

Garmin SAE5-35 |

$349.00 |

$349.00 |

|

1 |

Wiring Harness - built by vendor |

Pacific-Coast Avionics |

custom |

$740.00 |

$740.00 |

|

1 |

Autopilot |

Pacific-Coast Avionics |

Trutrak Digiflight 200VS GPSS |

$4,235.00 |

$4,235.00 |

|

1 |

Firewall Forward Kit |

Vans Aircraft |

FF-7/7A IO-360 CS |

$4,600.00 |

$4,600.00 |

|

1 |

EFIS |

Grand Rapids

Tech |

Dual Display EFIS w/ AHRS |

$8,995.00 |

$8,995.00 |

|

1 |

ARINC Bi-Directional Interface |

Grand Rapids

Tech |

ARINC 429 |

$475.00 |

$475.00 |

|

1 |

Fuel Totalizer |

Grand Rapids

Tech |

Fuel Flow Option |

$375.00 |

$375.00 |

|

1 |

CS

prop, Jihostroj P920 Governor |

Whirlwind Propellers |

WW

151 RV, P920 Gov. |

$7,500.00 |

$7,500.00 |

|

|

|

|

|

TOTAL |

$63,245.00 |

|

| 1/30/04 |

Well the process of getting financed is complete.

Today I received multiple checks for all the above mentioned products.

I'll mail them out on Monday. By March my garage is going to be very

full of aero stuff. I can't wait. Pics of checks.

|

| 1/31/04 |

Dave Bristol, our EAA chapter 96 Technical Counselor, Flight

Advisor, and Board Member graciously came by for my third EAA Technical

Counselor Visit today. I always enjoy talking to Dave as his

experience building his RV 6 are essential to my successful completion of

the project. Dave gave a good look over and indicated that I was on my

way to a nice flying bird. He also suggested that I get some flying

under my belt and not wait till the plane was almost finished. I

concur. I need to get some air under my wings, and soon.

Tomorrow I will send a little over $63K worth of checks out to get the parts

mentioned above. No progress to mention except cleaning up all the

edges of the remaining parts for the interior of the fuselage. I've

still not been able to get someone over here to help finish the fuselage.

I'll be leaving for France from Feb 5-10. When I come back my parents

are going to come for some here for several weeks. Me and Mom and the

Old Man will knock it out then. |

| 2/22/04 |

Well after a very long hiatus from doing any riveting on the

fuselage I was finally able to get some help today. My very good

friend Scott Dewald stopped by this

weekend and we shot a few hundred rivets. After that I prosealed the

firewall to the side and bottom skins. Getting that proseal out of the

tube took some work! Finally back in action.

|